SMP-Tex – super-micro pores

Particles that penetrate deeply into the filter media can only be removed with difficulty by cleaning. This leads to an increase in the differential pressure over time and ultimately to clogging of the filter media so that the filter elements must be replaced. One of the most important factors in the development of innovative filter media for filtration systems is always the optimisation of surface-oriented particle separation.

Surface-oriented particle separation

- Reduces particle deposits and lowers the differential pressure,

- Reduces cleaning frequency due to longer filtration cycles,

- Conserves energy and lowers operating costs.

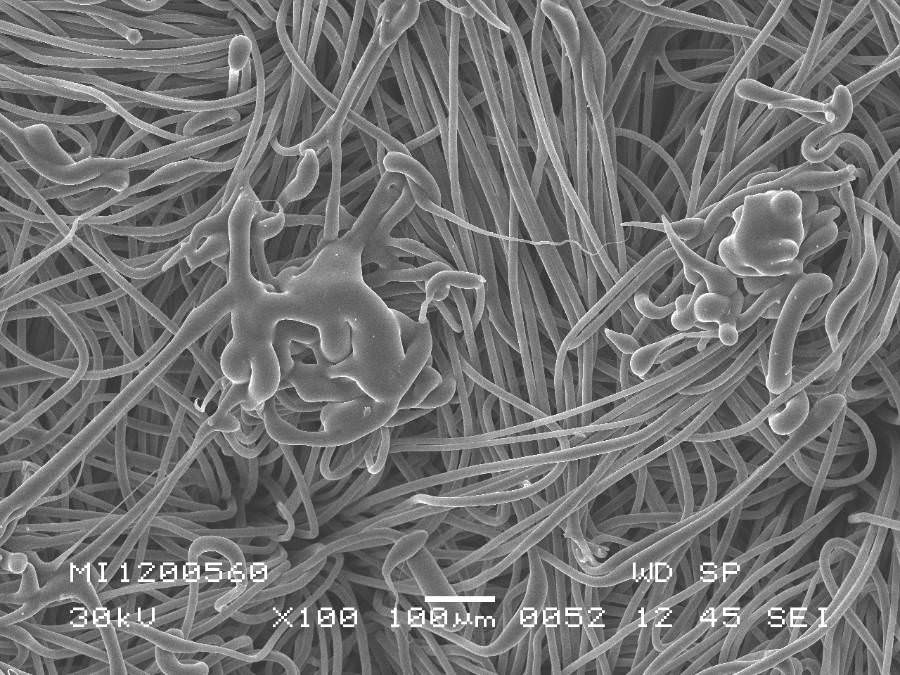

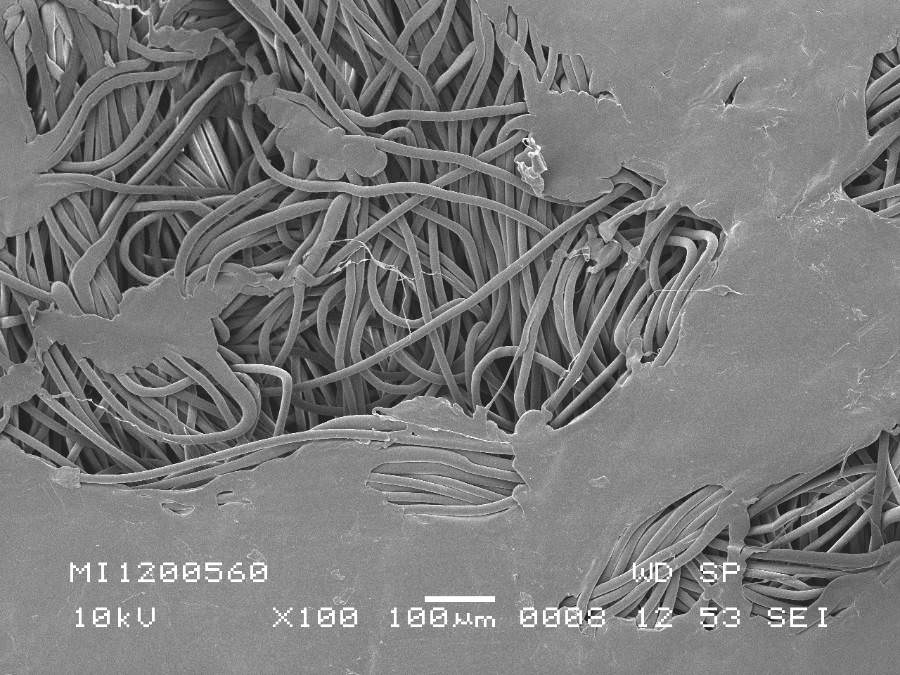

The innovative SMP-Tex filter media were specifically developed for the separation of finest, dry dust particles. Innovative high-tech fibres and a special treatment method are used in production, whereby extremely fine pores are generated on the upstream side of the filter media. These extremely fine pores are responsible for optimum surface filtration and a low rate of residual pressure loss.

Even the finest dust particles are separated on the surface and the penetration of particles in the cross-section of the filter material is reduced to a minimum.

Benefits

- Extremely fine micropores

- Emissions below 1 mg/m3 possible

- Extremely good cleaning results due to the smooth surface

- Low differential pressure

- Low compressed air consumption

- Stable operating performance

- Cost reduction due to less compressed air, filter replacements, transport and waste

- Suitable for air recirculation (dust category "M")

- Much larger open filter surface in comparison to standard filter media of dust category "L" or "M" as not calendered

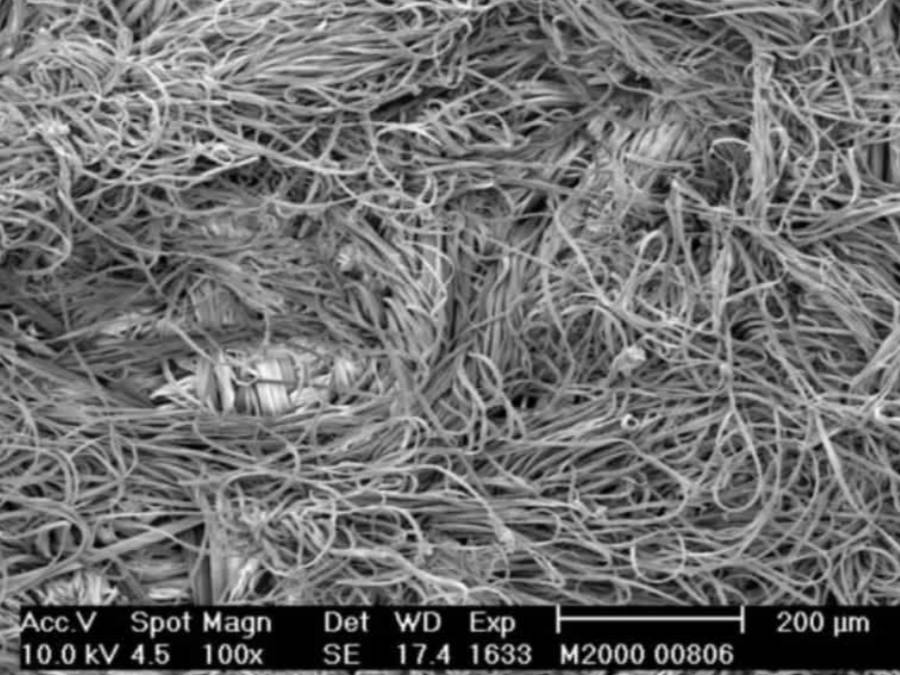

Upstream side* of a 550 g/m² standard needle felt Singed surface, air permeability 150 l/dm² min at 200 Pa

(*) The same enlargement scale is used in all four images.